wet compression test steps|acceptable compression test results : inc To perform the wet test, a tablespoon of engine oil, is poured into the cylinder, through the spark plug hole. So, you squirt the tablespoon of engine oil, into a cylinder, that is . webAbout Press Copyright Contact us Creators Advertise Developers Terms Press Copyright Contact us Creators Advertise Developers Terms

{plog:ftitle_list}

3 de mar. de 2021 · The Miceli family won $10,000 on Family Feud Canada is helping to raise autism awareness in Windsor, Ont. on Wednesday, .

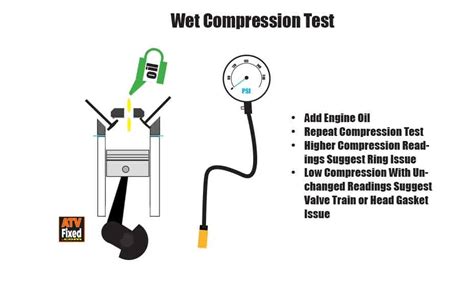

Wet Compression Test. Cylinder compression tests identify combustion engine cylinders with poor compression. If a cylinder has low compression, perform a wet compression test to indicate whether a bad valve, head gasket, or worn piston . To perform the wet test, a tablespoon of engine oil, is poured into the cylinder, through the spark plug hole. So, you squirt the tablespoon of engine oil, into a cylinder, that is . AFTER YOU HAVE DONE A BASIC COMPRESSION TEST, THE NEXT STEP IS, WET COMPRESSION TESTING. Above all, an engine needs a good seal between the rings, . To perform the wet test, a tablespoon of oil is poured into the cylinder through the sparkplug hole before checking the compression. On horizontal cylinders, oil does not spread evenly over the piston crown, a .

Check out the video on compression testing first. If you have a low (not 0) cylinder, a wet compression test is a common next step. Wet Compression Test: Add a small amount of oil to the cylinder and retest compression. If compression increases, it suggests worn piston rings. Cylinder Leak-Down Test: This test measures how much pressure is lost in . How To Perform A Wet And Dry Compression Test And How To Read The Results. Brian Eslick from How to Automotive http://www.howtoautomotive.com takes you .

A “wet” compression test can be done after the standard test. Squirt a teaspoon (or less) of 30W motor oil into each cylinder, then check the compression again. The oil will help seal any broken piston rings temporarily . Brian Eslick from How to Automotive http://www.howtoautomotive.com takes you step-by-step through the process of preforming a wet and dry compression test . AFTER YOU HAVE DONE A BASIC COMPRESSION TEST, THE NEXT STEP IS, WET COMPRESSION TESTING. Above all, an engine needs a good seal between the rings, and the cylinder walls. Also, between the valves, and the valve seats. On a healthy gasoline engine, compression usually falls between, 125 and 180 psi, depending on your make and model.

wet compression test vs dry

Familiarize Yourself with the Engine: Before starting the compression test, it is essential to have a good understanding of the engine’s layout and components.This knowledge will help you locate the necessary and access points for the test. Ensure Proper Ventilation: Compression testing involves running the engine, which produces exhaust gases.To prevent . The equivalent compression reading for a cylinder that should be 135 PSI by the data at 5000′ would be 135 x .8617 = 116.33. Wet Compression Test. Many automotive books describe a dry and a wet compression test. Usually, these tests must be interpreted together to isolate the trouble in cylinders or valves. How to perform a compression test. The steps involved in performing a compression test will vary depending on your type of engine, so make sure to refer to a workshop manual for specific instructions on your car. . A “wet” compression test can be done after the standard test. Squirt a teaspoon (or less) of 30W motor oil into each cylinder .

A compression test diagnoses many engine problems. If a compression test is below the manufacturer's specifications, there's an internal engine issue. How It Works. Pricing. . Step 15: Remove the compression gauge from that cylinder by . A compression test will reveal the state of your engine’s parts, and can potentially save you money on buying a replacement engine. How It Works. . If you are thinking about completing a compression test, there are 5 important, general steps to follow to ensure it’s as accurate as possible. Always refer to the recommended instructions for .

spiral torsion spring tester

A detailed video on how to do a wet compression test and a dry compression test. We also cover leak down testing and engine diagnostics. SUBSCRIBE for more a. Testing the engine compression on your Chevrolet or GMC 4.8L, 5.0L, or 6.0L engine is not hard to do. A compression test will help you to determine the health of your engine by measuring the pressure of the air that gets compressed by the . This tutorial will teach you everything you need to know to do a compression test on any engine. I cover the process from start to finish including what comp. STEP 2 Start the threaded end of the compression gauge in a spark plug hole by hand. STEP 3 Turn the ignition on, depress the throttle, and crank the engine four revolutions.

Worn valves, valve seats and valve train normally cause uneven compression. If only one cylinder has low compression, a burned exhaust valve, broken valve spring or broken piston rings are indicated. Dry/Wet Compression Testing – The classic wet/dry compression test is intended to detect worn piston rings by comparing cranking compression . Follow these steps to guarantee a smooth testing procedure: Remove the spark plugs: Utilize the appropriate tools to extract and inspect the spark plugs, . To determine if the problem lies with piston rings or valves, consider conducting a wet compression test on cylinders with low pressure.If the compression is low in a cylinder, it's time to find out why. Use the leak down test to know if you should be changing head gaskets, valves, piston rin.

An engine compression test gives a great insight into the condition of piston rings, valves and head gasket and can inform your next move in tuning your engine. . Repeat these steps for each cylinder: . engine oil into the .

The compression test is a procedure that measures the ability of a cylinder to contain the pressure produced while the piston is traveling upward with both valves closed. The four strokes are: . The first step is to warm up the . Cooley shows you how to do the king of all engine tests.Subscribe to Roadshow: http://bit.ly/1Z3Ff7GVisit us online at http://www.TheRoadshow.comTwitter @Roa.Compression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using platens or specialized .The test is conducted for 5 moisture contents to obtain the optimum water content (w opt), for which the value of the dry unit weight is maximum (γ d,max). Test Equipment. The equipment utilized to conduct the test includes: 10-centimeter diameter cylindrical compaction mold equipped with a base and a collar

A compression test is an excellent way to determine the condition of your engine. Among many other things, it will reveal the state of the valves, cylinders, rings, valve seats, and how these parts are wearing out. If you notice your engine generating low power than usual or running rough, consider carrying out a compression test to find out the problem. For this step, go to: TEST 2: Wet Engine Compression Test. TEST 2: Wet Engine Compression Test To find out if the low compression or 0 PSI compression reading you got in TEST 1 is due to bad piston rings or bad cylinder head valves, you need to perform a wet compression test on the affected cylinders.

Step 2: Attach the Compression Tester Hose. Screw the hose-end of the motorcycle engine compression tester into the cylinder you are interested in (finger-tight). Good compression tester kits come with various adapters allowing for the testing of a wide variety of engines. Step 3: Open the Throttle Repeat test steps 3 - 5 on the remaining cylinders. Let's examine your test results: CASE 1: One or two cylinders had a much lower compression value than the others. Up to a certain range, this could be normal. . For this test go to: TEST 2: Wet Engine Compression Test. CASE 3: The compression value of all six cylinders was similar and above .

This means that cylinder #4, which has a compression value of 120 PSI, is the one causing the misfire (P0304) because it's below the 144 PSI minimum. Once we've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Compression Test. TEST 2: Wet Compression Test

Worn valves, valve seats and valve train normally cause uneven compression. If only one cylinder has low compression, a burned exhaust valve, broken valve spring or broken piston rings are indicated. Dry/Wet Compression Testing – The classic wet/dry compression test is intended to detect worn piston rings by comparing cranking compression .

Crank the engine five times and record the wet compression reading for that cylinder next to the dry compression test result. Now repeat step 7 to safely remove the engine compression gauge kit and proceed to the next cylinder. 9. Test other cylinders . To further probe the worn piston rings problem, check the wet compression test results. If .

interpreting compression test results

spiral torsional spring tester

sprint car torsion bar tester

21min. TV-PG. Golden Globe Award winner Matt LeBlanc stars as Adam, a contractor who starts spending more time with his three kids when his wife, Andi, goes back to work and discovers the truth all parents eventually .

wet compression test steps|acceptable compression test results